MAKING THE RIGHT BRICK SELECTION FOR YOUR INTERIOR

Bricks are one of only a few building materials that have lasted for centuries. In fact, the practice of brick making dates back before the Roman times and while modern production may have improved the process, the fundamental practice of brick making and the raw materials used, remain very much the same today as they were thousands of years ago.

In essence, natural clay bricks are made from three main ingredients – clay, water and fire. It’s really quite simple; we take clay from the earth, we break this clay down into finer particles, we add water, we shape clay to the desired size and add texture to the face and then we fire the clay at over 1000 degrees centigrade in a kiln. The firing process usually takes about 4-5 days between drying, firing and cooling (depending on the kiln type).

As brick making evolved, so too did the selection of bricks that are available, so much so that today, we have thousands of colours, sizes and textures to choose from. Thanks to the character that bricks can add to facades and interiors and the fact they’re also a highly durable eco-friendly material, bricks are very much the preferred choice of most architects nowadays.

With only one operating brick factory remaining in Ireland (Kingscourt Bricks of Cavan), the current Irish market very much relies on imported bricks. For the most part, these bricks are sourced from Belgium, Holland and the UK and provide us in Ireland with an amazing selection of quality bricks to choose from.

Sometimes the selection process can be a headache. After all, bricks aren’t like wallpaper; once they are up they are usually there for a long time so one must select the right one.

Here are a few tips on what to look for when selecting a brick for interior use:

Full brick or brick slips

The first question to ask yourself is “full brick or brick slips?”

A brick usually measures 215mm in length, 65mm in height and 102.5mm in depth. If this is a retrofit project and a room is lacking space to add a full brick or if you would prefer not to have wheel barrows, cement mixers and brick layers working over your good living room floor, a brick slip is the right choice.

Brick slips are bricks that have the back cut down from a depth of 102.5mm to 20-30mm, making them a brick tile rather than a brick. Most handymen can install brick slips but finishes are usually better left to the professionals (which doesn’t have to be a brick layer or a tiler). We would recommend that you ask your brick distributor for advice here.

In most cases, new builds excluded, brick slips will be the preferred choice. Brick slips are applied to a wall/existing surface with adhesive and pointed after. It is very important to discuss the suitability of the surface for applying slips and we must consider how the area will behave with the weight of applied slips and mortar – most of these questions should be discussed with your provider or your architect if you have one, in advance of ordering.

A guide to installing brick slips can be seen on https://www.outhaus.ie/applying-brick-slips/

Brick slips are usually made to order but some good brick stores may have products available off the shelf. In most cases they can be purchased as individual pieces or in half meter square boxes. Corner pieces are also available.

Once you have the technical part out of the way it’s down to the fun part……..colour, texture & style.

Style

There are numerous types of bricks manufactured for various types of construction requirements and each have very different characteristics. For example, engineering bricks are used for barring heavy loads or in areas of severe weather exposure. Usually engineering bricks are less attractive aesthetically in plain blue, brown or red colours, with a smooth face and a heavy appearance – not what most would like for internal use.

Brick types that are normally used on internal areas are as follows (for non-structural use) – by order of popularity (most popular at the start).

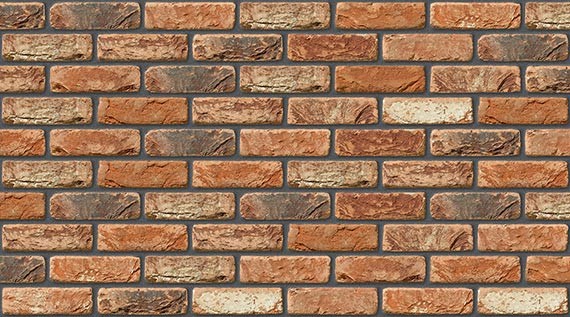

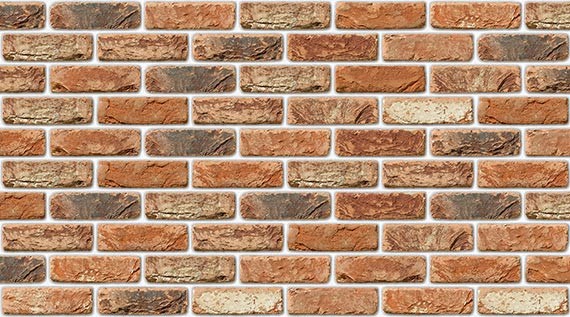

Handmade bricks

These days, most handmade bricks are made by machine but classed as handmade because of the process of dropping clay into a mould and flipping it back out. This process of dropping and flipping the clay gives the face of the brick an old roughened appearance and uneven sizing. Overall a handmade brick will give a classy old world style.

Tumbled handmade bricks

Tumbled handmade bricks are handmade bricks that have been put in a very large cement mixer and rolled around to knock off the edges and slightly roughen up the brick. This will give a reclaimed brick effect.

Stock brick

Stock brick is a more modern production method, similar to handmade with the use of moulds but packed into the mould with sand and then pressed, by machine, to give a cleaner smoother face. Stock bricks will give a slightly more contemporary classy style.

Water Struck bricks

Water struck bricks are like stock bricks but the face has been blasted with water to distort the texture. Water struck brickwork provides a classic effect with a modern twist.

Wirecuts

Wirecuts are modern day machine-made bricks that have been cut with wires from a clay slug. The cutting by wire gives these bricks a more perfect size and shape, and overall the brickwork will appear with very straight lines. These will be used for a more contemporary finish.

Pointing

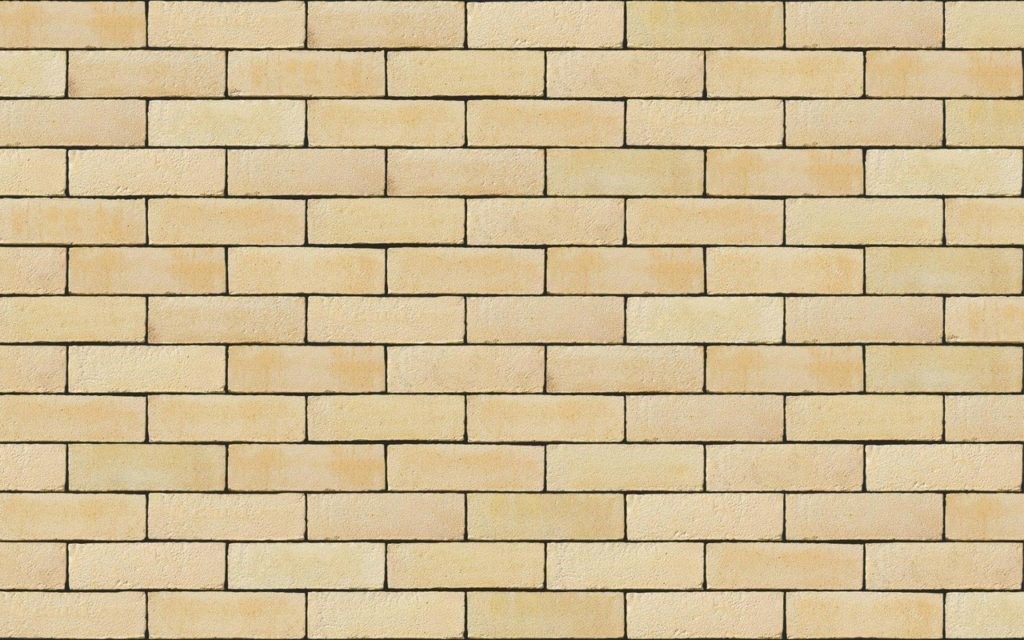

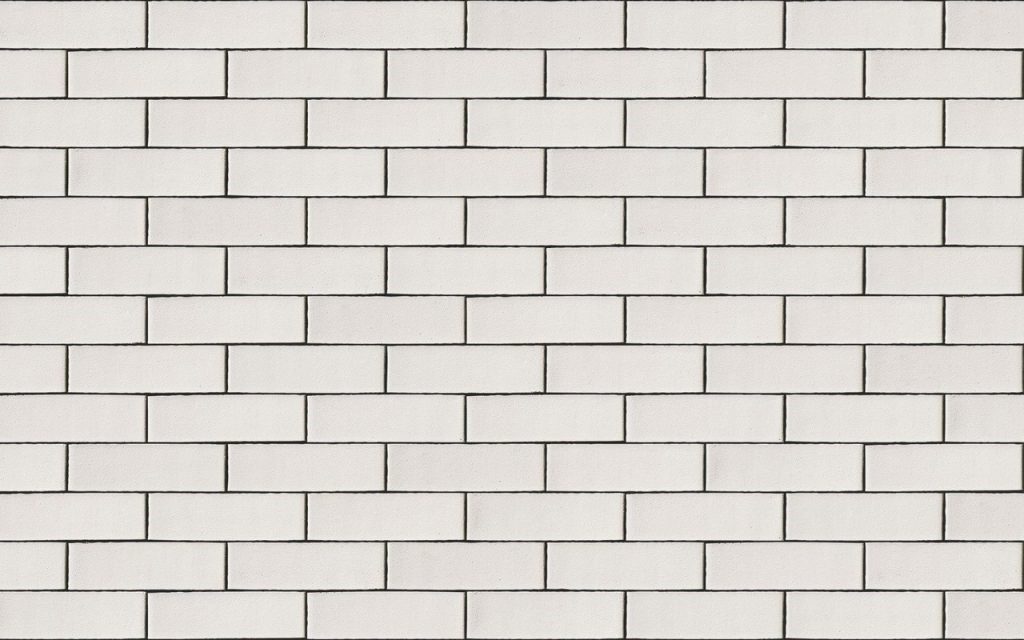

With a standard sized mortar joint, mortar becomes 20% of the overall visual on completed brickwork. So the mortar colour can have a significant effect on the overall finish – see below for examples and choose wisely. Dark coloured pointing will stand out on light bricks and light pointing will stand out on dark bricks.

You can see from the images below how different the same brick can appear with two different mortar selections.

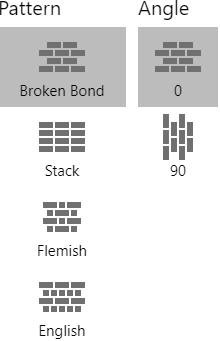

Have a look at our product visualiser on the outhaus website homepage. Select interiors and choose interior cladding and then select cladding library and click on the brick slip you want to view and then click on the product visualiser and you can change the mortar colour and bond pattern.

Zero joint brickwork

We have seen the significant effects that mortar can have on the brickwork. In response to architect’s requests, we have introduced joint-less brickwork. There is a specific brick for joint-less brickwork but this is not the case when using brick slips so if you like the effect, this can be a very simple way to clad an internal area without the hassle of mortar.

Choose your brick bond

Over the past 50 years, brickwork in Ireland and the UK has very much been, what we refer to as stretcher bonds. This is where we lay bricks on top of each other with a 50% overlap on each course. Previously, brickwork was so much more creative and we used patterns such as English garden bond, a header and stretcher bond (see below). In the past few years, we have seen a resurgence in bond patterns moving away from a stretcher as architects push boundaries and try for something more unique. Changing patterns can really influence and enhance the over style of brickwork.

Stretcher bond

Flemish bond (mix of headers and stretchers or full and half bricks)

Vertical brickwork

Finally and most importantly, choose a colour. Bricks are available in almost any colour but the most popular are yellow, red, buff, brown, black and grey. Some are mono toned but most are multi colours which give the brick character. If you are choosing a brick for internal use, do consider the light in your room and how the brickwork may brighten this up or tone it down if required. Dark coloured bricks will dominate a room but so too will bright. Unless you have a very particular design brief, we advise the use of paler more neutral colours which won’t tire over years.

It is always advisable to consult with an architect or engineer before commencing any renovation project.

Internally, bricks can be used anywhere – walls, ceilings, bathrooms, kitchen splash backs…